Sandvik Optimine®

OptiMine® enhances mining operations

Sandvik industrial group is a pioneer in digital solutions for the mining industry. In a traditional industry, digital solutions are utilized both in the automation of work machines and in the optimization of production. For both, Sandvik offers solutions that also have Symbio’s fingerprint in their code.

“I like Symbio’s strategy. Accordingly, they are proactive, bringing ideas and good solutions to the table at just the right time. This has deepened our cooperation and developed it in the right direction, ”says Ville Svensberg, Strategic Offering Director at Sandvik’s Rock Drills and Technologies unit.

“A long-term partnership always benefits the product being developed. It also brings continuity to doing because we know each other’s strengths. The good and confidential relationship that has developed over the years has resulted in Symbio engineers now partially developing subassemblies into our products. This is based on Symbio’s understanding of our customers’ needs and aspirations. ”

At best, Sandvik’s development teams have had a dozen or so Symbio developers to code the software and take care of testing and quality assurance.

“With external resources, we get the mix of different skills and margin we need. At Symbio, we have found the right people to do the right things, often guided by our job coaching. Everyone has their own important role to play as a whole, ”says Svensberg.

OptiMine® enhances mining operations

After the development of AutoMine®, a remote control and analysis system for mining robots, Symbio has continued to work with Sandvik’s development team for other software solutions, such as OptiMine® production control software.

OptiMine is a software product that enables global mining companies and mining subcontractors to plan work tasks and time usage, report on day-to-day events, and analyze job performance data. The software consists of modules from which the customer can select the functionalities relevant to their operations.

“OptiMine offers our customers transparency in their own production. The software we create is like a toolkit, which means that the development of operations is always based on proven knowledge, ”Ville Svensberg describes.

What unites Sandvik’s customers using OptiMine is that they understand the added value that new technologies bring to their own operations. A major breakthrough in the digitization of the mining industry took place at the end of 2016.

“In the mining industry, digitalisation took place later than in many other industries, but now they are ready to go digital. Sandvik’s OptiMine is excellent at meeting operational analysis, monitoring and other operational challenges, ”says Ville Svensberg.

Predictability brings cost savings to mining

With OptiMine, work instructions are displayed on the machine screen. As the work progresses, it will be reported to the mine’s central control room and database. With the help of the analysis module, it is possible to find delay elements in production and predict the need for equipment maintenance. The information can be used to prevent potential production disruptions, which increases productivity, predictability and savings.

“We work closely with our customers and develop many products together with them. We recognized the need to optimize work supervision years ago. Now we have to offer a finished, modern product when the industry is ripe to take advantage of it. With OptiMine, our customers are able to increase utilization and thus productivity when resources are utilized based on real-time data, ”says Ville Svensberg of Sandvik.

08.02.2022 | References

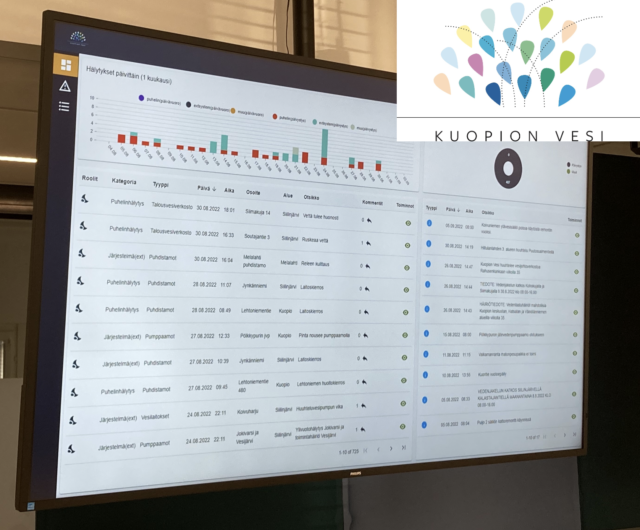

Kuopion Vesi – Better User and Customer Experience with New Communication Platform

Kontram – New Business with Edge IoT Solution