Kontram – New Business with Edge IoT Solution

”We wanted a modern solution with no hardware or software lock-in”

– Henri Honkonen, Kontram

GOAL: DIGITALIZATION OF INDUSTRIAL PROCESS MEASUREMENT SYSTEMS

Kontram is one of the biggest industrial automation, valves technology, and process measurement products and solution providers in Finland. Kontram’s wide product range includes industrial measurement devices, regulators, testing devices, electric components and machine automation systems. Common use cases are for example industrial process control, emission measurement, and indoor logistics automation. Kontram’s customer base covers all largest industries from energy to mining industries.

”We wanted a modern solution with no hardware or software lock-in” – Henri Honkonen, Kontram

Kontram’s goal in the project was to improve the utilization of measurement results and device diagnostics, and modernize the data handling and analysis systems. Previous solutions had very limited features and for example measurement results could not been accessed remotely, but only using the local user interface of the device. Also, the user interfaces of emission measurement systems have not been configurable according to customer’s needs. “Our previous system had a lot of technical limitations and we had to make compromises in our solutions for clients. When we started to dig deeper into the problem, we realized that now it’s the time to make a total modernization of the system instead of incremental improvements. That enables us new business opportunities as well” summarizes Kontram’s technical product manager Henri Honkonen.

Fast Implementation with Symbio’s Edge IOT Solution

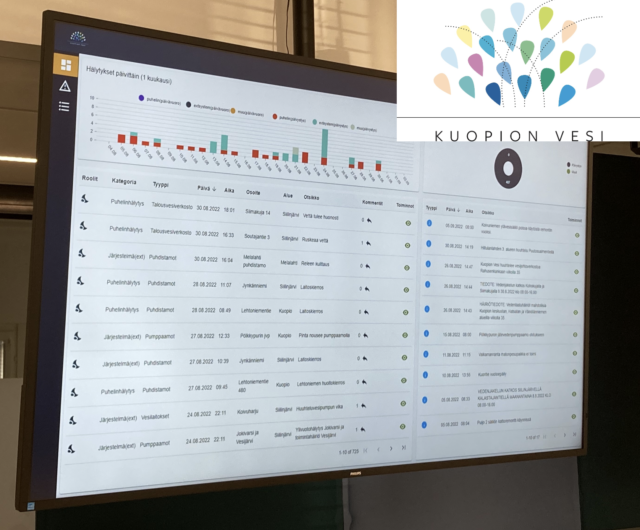

Symbio’s Edge IoT solution enables data utilization both on the local user interface and remotely using a cloud service. New features enable parameter setting and users can create rules for alerts. Sensor metrics are available both for short- and long-term analysis, and the system is configurable based on the user needs. Data is always stored in the cloud for later analysis needs. The user interfaces are also fully configurable and they can be updated remotely.

Symbio’s Edge IoT solution is based on Microsoft Azure IoT platform. The platform offers many features, such as data security, software updates and system monitoring out of the box. This means that development efforts in the project can be put in building the solution itself and not in the setting up of basic functionalities. “Flexibility and out of the box features of IoT Edge platform, along with Symbio’s experience in the technology were significant factors when we made the decision on the solution provider”, Honkonen comments.

Digitalization Creates Value

New solution is more flexible compared to the old one and it enables solving customer’s problems remotely. User interfaces are configurable according to the customer’s needs and data can be analyzed on-site or using a Web user interface. “With digitalized solution, we can offer better service to our customers. Previously, problems have been solved with telephone calls or on-site customer visits, which have been very time consuming. New solution enables preventive maintenance, because now we get fault analyses and diagnostics data online no matter where the customer is”, Honkonen describes.

Symbio’s flexible and open Edge IoT solution enables also future development possibilities. For example, adding machine learning and AI components would improve the predictability of maintenance needs and make the service even more proactive. Pre-emptive maintenance could be offered as a value-added service for customers and maintenance could be done whenever needed and not only during annual maintenance breaks.

21.02.2022 | References

Kuopion Vesi – Better User and Customer Experience with New Communication Platform

Suunto – Reliable Quality Assurance at Night Shift